Our Solutions

Farm and forest residue

Farm waste, particularly lignocellulosic waste that is difficult to compost, poses a challenge for farmers. In the Central Valley in California in 2020, 600,000 tons of agricultural biomass was burned in open air. Enventix collects this waste and converts it to value for farmers.

Sustainable Aviation Fuel

The need for massive reductions in carbon emissions demand that planes use renewable biofuels. Enventix converts biomass into bio-oil that is refined into SAF and other fractions. This biofuel reduces carbon emissions enormously compared to fossil-based or first generation biofuels from food feedstocks.

Organic farming products

Enventix doesn’t just help slow climate change. We also help farmers adapt to it. Our advanced conversion of biomass creates two optimal products to put organic nutrients from biomass waste back into the soil and crops: biochar, a persistent, solid soil amendment and wood vinegar, a holistic growth booster that can be added to irrigation systems.

Carbon sequestration

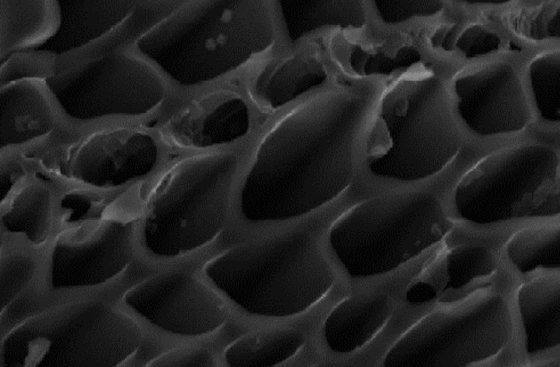

Plant biomass is short lived material that ultimately decomposes by microbes who respire it as greenhouse gases CO2 or CH4. Our production of biochar averts this fate. Biochar is highly porous, solid carbon that is stable in soil for 100 to 1000 years. It is one of the few economically viable ways to verifiably sequester carbon while it also creates huge value in its application to soil and elsewhere.

Digestate

Anaerobic digestion of wet organic waste to capture methane leaves behind a digestate that is rich in organic material. Enventix can convert generate high value for this material by converting it into bio-oil, biochar, and wood vinegar.

Municipal solid waste

Enventix's conversion process is a technological breakthrough that can safely convert unrecyclable paper and plastic and the residual digestate from anaerobic digestion to biofuel and biocarbon. The Integrated Materials and Energy Recovery Facility that we developed with our partner Zero Waste Energy breaks barriers of cost, efficiency, reliability, feedstock flexibility, and scale to bring cities closer to making zero waste a reality.

Oil sludge environmental cleanup

Enventix has designed a solution to use its technology to separate out light crude, water, and carbonized sand from sludge. Sludge ponds can be cleaned up within a 2-year payback period due to the value of the conversion products. Modular conversion plants can be trucked right to cleanup sites, multiple modules can be used at large ponds, and plants can be relocated once sludge conversion is completed. Contact Enventix to discuss if this solution can help your sludge problem.